A continuous commitment to skills development

Intercolor Training Center

The benchmark in paint and anticorrosion training

We are always ready to help.

- Understanding corrosion phenomena in order to design and ensure long-lasting protection.

- Learning surface preparation techniques.

- Mastering protective products as well as application methods.

Training delivered by experts

Experienced trainers dedicated to developing your skills.

Our trainers have significant professional experience directly related to training activities, as well as strong teaching skills that enable them to cover a wide range of training topics.

Our Training Programs in Painting

- Surface Treatment

- Surface Preparation

- Paints and Varnishes

- Application Techniques

- Paint Defects

- Corrosion

- Tests and Inspections

- Anticorrosion Painting Works

- Health, Safety & Environment (HSE)

Surface Treatment

Optimizing the performance and durability of coatings.

- Objectives of surface treatments

- Classification of surface treatments

- Different types of surface treatments: on steel, light alloys, composites

- Influence of surface treatments on coating adhesion

- Chemical surface treatments

- Mechanical surface treatments

Surface Preparation

- Objectives of surface preparation

- Logical sequence of surface preparation operations

- Degreasing

- Stripping

- Products and tools used

- Manual preparation

- Abrasive blasting

- Abrasive blasting techniques and equipment

- Degrees of cleanliness

- Roughness

- ISO standards 8501-/2, 8503, 12944

Paints and Varnishes

Paints and varnishes that combine aesthetics and performance.

- Definition of a paint

- Components of a paint and their roles

- Methods of drying and curing paints

- Technical data sheet

- Selecting a paint according to client requirements

- Paint systems

- Preparation and application of paints

- Application conditions (temperature, humidity)

- Coverage rates

Application Techniques

Mastering processes for optimal results.

- Methods of applying liquid paints

- Comparison of different processes

- Selecting the process according to the paint type and the expected result

Paint Defects

- Identification of defects before, during, and after application

- Causes and remedies for different defects

Corrosion

Understanding the mechanisms to better protect materials.

- The behavior of different families of metals in relation to the environment

- The main causes of corrosion

- Types of corrosion

- Degrees of rusting

- Aggravating factors

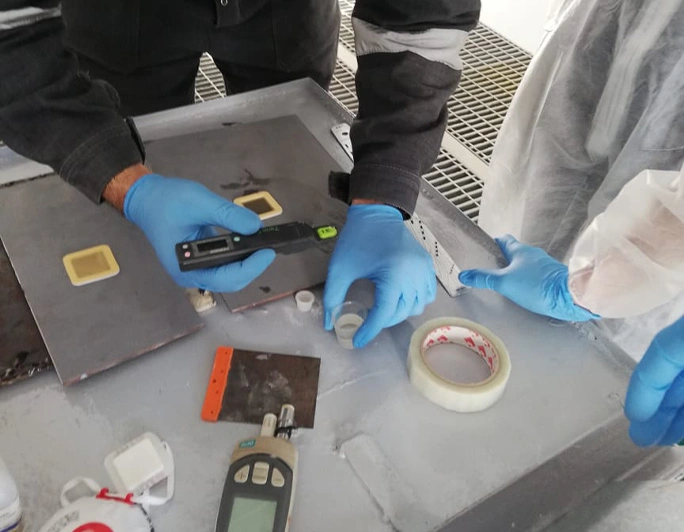

Tests and Inspections

Accurate testing for guaranteed results.

- Evaluation of the initial condition of the substrate

- Measurement of atmospheric conditions

- Inspections carried out during the process:

- Assessment of cleanliness level

- Measurement of surface roughness

- Measurement of wet film thickness

- Measurement of dry film thickness

- Adhesion testing

- Gloss measurement

- Porosity measurement

Anticorrosion Painting Works

A structured methodology for lasting results.

- Specifications

- Price study

- Key focus points

- Implementation

- Project monitoring

- Traceability

Health, Safety & Environment (HSE)

Risk management and compliance with standards in painting environments.

- Risks in the paint workshop

- Collective protections and personal protective equipment (PPE)

- Labeling of paints and solvents, workshop signage

- Safety Data Sheet (SDS)

- Hazardous products and common sources of pollution

- Risks from paint components and solvent emissions

FAQ – Intercolor Training Center

1. Who is the training offered by Intercolor intended for?

The training is designed for painters, technicians, engineers, supervisors, and design offices wishing to acquire or strengthen their skills in anticorrosion, industrial, or automotive painting. It is also intended for anyone working in demanding technical environments.

2. What are the main objectives of this training?

The objective is to train participants in a highly technical profession that is rarely covered by traditional programs. Learners acquire comprehensive skills: surface preparation, paint application, mastery of processes, knowledge of standards, defects, quality control, as well as health, safety, and environmental requirements.

3. Who are the trainers at the Intercolor Training Center?

The training sessions are led by experts with solid professional experience directly related to the industrial painting trade. Their pedagogical skills enable them to effectively transfer technical know-how and best practices from the field.

4. What topics are covered during the training?

The training covers all stages of the industrial painting profession: surface preparation, paint application, application techniques, defect identification, quality control, corrosion, safety, and compliance with standards.

5. Does the training cover current standards and regulations?

Yes. Participants are trained to read and apply relevant standards such as ISO (8501/2, 8503, 12944), traceability requirements, as well as industry-specific quality and safety standards.

6. Do participants carry out practical applications?

Yes. In addition to theoretical input, the training includes practical sessions to practice surface preparation techniques, liquid paint application, substrate inspection, and the identification of common defects.

7. How are workshop risks managed?

The training includes a comprehensive module dedicated to hygiene, safety, and the environment. This module covers workshop risks, the use of personal protective equipment (PPE), product labeling, safety data sheets (SDS), as well as sources of pollution and solvent emissions.

8. What is the advantage of attending training in a center attached to a manufacturer?

The Intercolor Training Center provides field expertise directly connected to product innovation. Participants benefit from up-to-date content, aligned with the latest paint technologies and proven application practices. This ensures concrete, hands-on training that is directly applicable on-site.